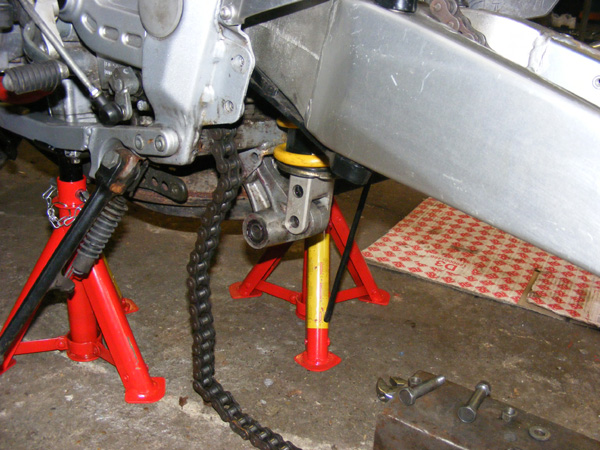

Starting with a look of the 3TJ Swing Arm from the Underside.

Whilst they could be worked round quite easily if you used the original shock or one of a similar style, the swing arm bracing fouled on any modern shock reservoir. Since the original plan was to replace the original shock, the 3EN swing arm was not for me.

Ok so now comes the trickier deal I have a 3HE 18" diameter * 4.0 wheel with a brand new tyre on it (the original blew out the day before 3TJ swing arm was due to be fitted and the 17" * 4.5 rim arrived ) I also now have a 17" rim etc.

OK, I decided that I would put the new tyre to work BUT all modifications to fit the 3he wheel must be temporary so the 17" wheel could be fitted at a later date

The problems are:-

1} The 3TJ axle is 20mm in diameter

2} axle slots in the swingarm are therefore 20mm wide

3} 3he axle is 17mm diameter

4} 3he 18" wheel has 17mm bearings & 20mm cannot be swapped in !!

Ok so lets take the problems in order the 3TJ swing arm requires a 20mm axle which cannot be fitted to a 3HE wheel since there are no readily available bearings with the correct outer diam and 20mm bore.

It therefor requires the 3HE 17 mm axle to be used and the 3tj swing arm be spacered out. Since the axle pullers are 20mm also, it is therefor simple to make a spacer that is a push fit into the axle puller but wide enough to fit the width of the swing arms axle slot.

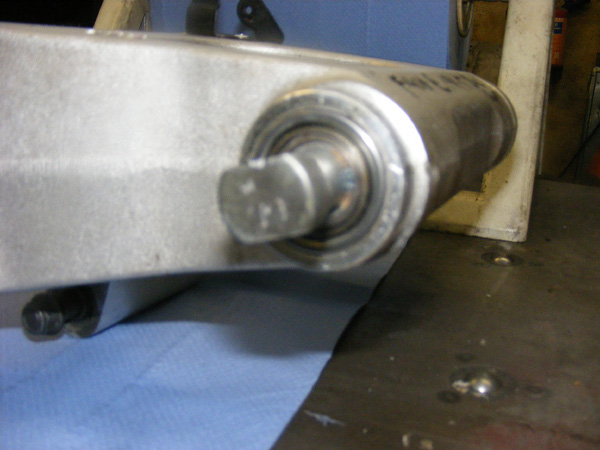

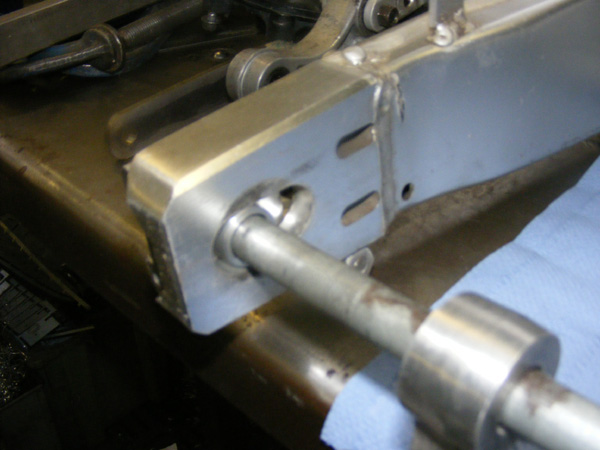

These can be seen in the two pictures below:-

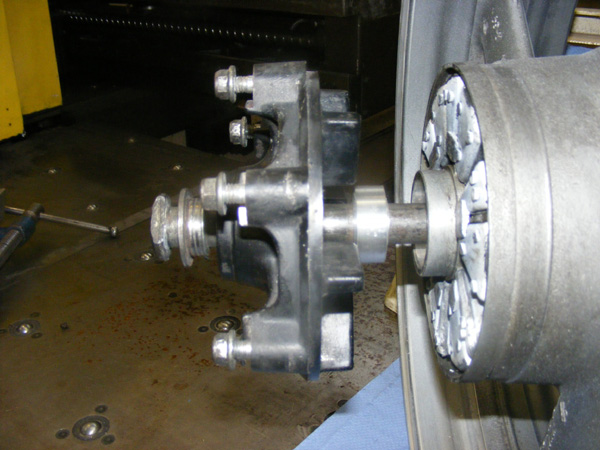

Since the caliper bracket will be used on both wheels at some point, I decided to bore out the bracket to 24mm and then double sleeve it. This has two purposes :-

A} allows the sleeve to be used as a spacer addition since the 3TJ swing arm is wider at the axle by 8 MM overall, so the sleeve is made 4mm wider than the caliper bracket but has a bore of 20mm that is additionally sleeved down to 17mm.

B} allows the spacer part to remain when the final conversion is done to 3TJ wheel and axle.

The last part of the conversion is to add 4mm to the sprocket side

spacer so that the wheel is centralised and the chain run in a

straight line

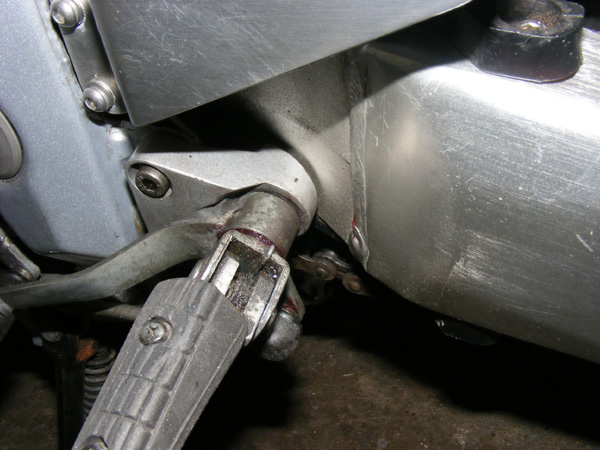

The right hand rider foot peg bracket clears the swing arm easily but the slip on exhaust does NOT clear the swing arm entirely and will need awasher inserted between the can holder and the passenger footpeg bracket.

The leftside rider peg bracket is the real hassle, as you will see

it required some very skillfull grinding to rear face of the

bracket to match the curve of the 3TJ swing arm to enable it to be

fitted.

Well that is 18" wheel fitted in the 3TJ arm, the saga continues

Ok so the bike is a FZR600 3HE 92 model and it has been fitted with a 3TJ (fzr400) alloy swing arm BUT still using the 17mm pivot bolt from the 3HE to hold the swing arm & the old 18" wheel for which good modern rubber si not redily available.

In the interest of getting sexier compounds for the tyres I decided to go with a 17" * 4.5 rim from the 3TJ which came with the rear disc but no sprocket carrier( Ebay sellers ??? ). I waited 6 months no sprocket carrier so i asked around and came up with thw 1WG model which was alledged to fit.

Alas like all things "well it should fit" it was almost a fit. the outer diameter was good & the cush drive fitted (3he is way too big and different cush drive fit entirely), the hassle was the 3TJ has a20mm axle and the 1WG has a 17mm axle so the cush drive bearing is too small or so it seemed. On closer inspection the bearing has a 20mm bore but has sleeved spacer internally that reduces the bearing bore.

By pushing out the spacer/sleeve the bearing is good to go.But as

always there is a GOTCHA, the cush drive needs to be spaced off

the wheel bearing. so the larger diameter of Yamaha's

spacer/sleeve has to be duplicated and used between the wheels

bearing and the sprocket carrier / cush drive bearing so the

wheel & carrier do not rub on each other.

To fit this new 17" wheel in the 3tJ swing arm it now only remains to remove the axle puller sleeves that were installed for the 3HE 17mm axle, together with the inner sleeve of the caliper bracket (leaving the 4mm spacer part in place) and fit the new wheel axle assembly as normal.

The GSXR 600 rear shock is just like the FZR shock in that it has a forked lower fixing (unlike R1's etc) but has a 50% stiffer spring rate and after market spring replacements if that is still too soft for your taste.

It is gas/oil controlled & has the usual preload adjustment which is not the usuall 6 or so settings but is infinitely variable. (you do need the special "c" spanner for this and some good arm muscles ). To match this it has rebound damping and compression adjustments both of which have clickable settings for easy memo taking when trying out your new ride (you do take notes don't you?)

Ok so what is likely as a GOTCHA:-

A} The shock is 0.5" longer

B} The top bushing is only 10mm diam NOT 12mm as on the FZR

C} the top bush is 10mm narrower than the FZR

To keep the ride height correct and compensate for the shocks

extra length you need new "dog bones" (shock linkages) that

have the mounting holes @ 138mm centers.

You will also need stepped bushes(2 pieces) that will have a

5mm thick 17 mm diam section with a further section 12mm diam

(bushing section to fit inside the FZR frame shock mount) that

is 10mm long and the thro hole is 10mm.

You will also need a 10mm diam bolt to replace the 12 mm diam

FZR version

It is worth noting that the bushes in the picture are

reversed the big diameter is supposed to be against the shock

head. This will then allow the bushes to slide into the frame

bracket holes !!

Gsxr shock top in place

Gsxr shock bottom inplace on the 3HE trilobe

Gsxr shock when it is all put together and just how

tight it all is